About

Our Services

Our Philosophy

Our Philosophy

Gayatri Auto Components specializes in precision-engineered PDC dies, trimming tools, gauges, and machine fixtures. With years of expertise, we leverage advanced technology and skilled craftsmanship to uphold the highest industry standards.

Our Philosophy

Our Philosophy

Our Philosophy

We aim to ensure and produce high quality products, Customer satisfaction, Timely delivery and at Competitive cost.

Our Mission

Our Philosophy

Our Mission

To solve real-world manufacturing challenges with reliable, high-performance dies and to build lasting relationships through trust and support.

Our Services

Design

VMC Programming & Machining

Simulate

We offer complete in-house die and mold design in close collaboration with our clients. This ensures that every detail reflects your requirements, resulting in tooling solutions that are both precise and tailored to your production needs. desire.

Simulate

VMC Programming & Machining

Simulate

Before manufacturing begins, we perform die flow simulation to analyze performance, identify potential production challenges, and optimize the design for maximum efficiency. This step reduces trial runs, saves time, and ensures consistent quality.

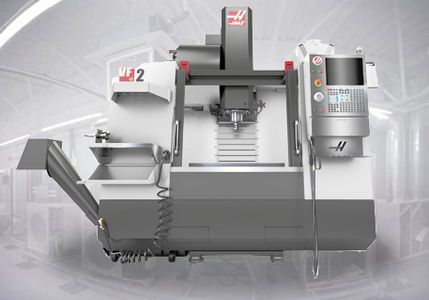

VMC Programming & Machining

VMC Programming & Machining

VMC Programming & Machining

Our HAAS VMC machines, built by the ISO 9001-certified largest machine tool builder in the USA, are programmed directly on the shop floor by our skilled team. This combination of expertise and advanced machinery guarantees high-precision machining for every project.

Final Inspection

Reverse Engineering & 3D scanning

VMC Programming & Machining

All products undergo in-house CMM (Coordinate Measuring Machine) inspection for accurate calibration and dimensional verification. This ensures that every tool and die meets your exact specifications before delivery.

Reverse Engineering & 3D scanning

Reverse Engineering & 3D scanning

Reverse Engineering & 3D scanning

Whether you need a prototype developed or an existing part replicated, our advanced 3D scanning and reverse engineering services can turn your concept into a production-ready design. This technology enables faster development cycles and seamless integration into your manufacturing process.

After-Sales Support & Maintenance

Reverse Engineering & 3D scanning

Reverse Engineering & 3D scanning

We provide comprehensive after-sales service to ensure the long-term performance of your dies and tooling. Our team offers maintenance, adjustments, and rework services, helping you extend tool life, maintain precision, and minimize downtime.

Shop floor

VMC Milling VF5

The HAAS VF5 is engineered for high-volume production with a larger Y-axis travel and extended work envelope, making it ideal for complex die mold applications. Its high spindle speeds, rapid tool changes, and superior surface finish capabilities ensure precision and efficiency in every cut.

VMC Milling VF4

A powerhouse for die manufacturing, the VF4 combines speed and accuracy with a robust build. It offers enhanced surface finish and dimensional precision, perfect for trimming tools and machine fixtures. Its larger work area supports versatile operations without compromising cycle time.

VMC Milling VF2

Compact yet powerful, the VF2 delivers high-speed machining with exceptional accuracy. Ideal for smaller dies and intricate components, it ensures consistent quality and reduced production time—making it a reliable choice for precision tooling.

Further Machines

- EDM ZNC

- Surface Grinding Machines

- Radial Drilling Machines

- Milling Machines

- Lathe Machines

Meet the Team

Sanjay Randive

Sanjay Randive

Sanjay Randive

I work as a Technical Manager for the team, using my experience to guide them in the right direction.

Ranjeet Mete

Sanjay Randive

Sanjay Randive

As the Lead Designer for the team, I ensure our product performs at its best in the market.

Our Projects

Contact Us

Better yet, see us in person!

We love our customers, so feel free to visit during normal business hours.

Gayatri Auto Components

K39, MIDC, Waluj, Chhatrapati Sambhajinagar, Aurangabad, MH, India

Hours

Open today | 09:00 am – 07:30 pm |